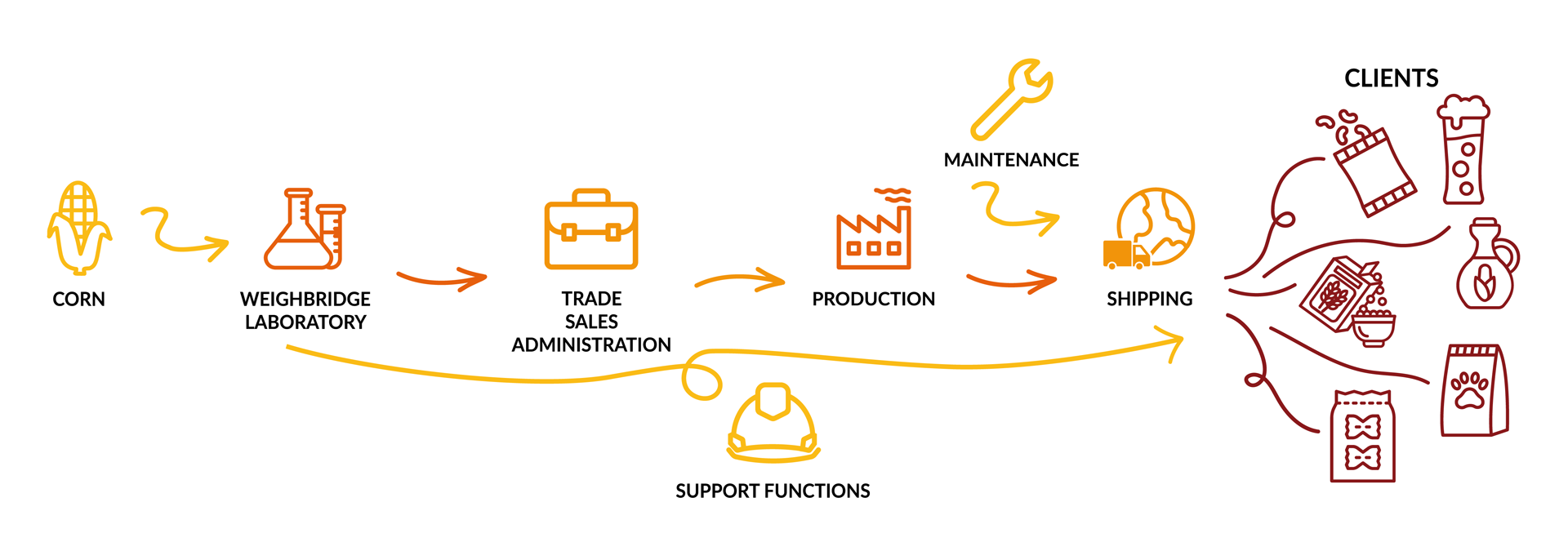

THE PROFESSIONS OF KALIZEA

WEIGHBRIDGE / LABORATORY / MAIZE CHAIN

Thanks to our development teams of the maize chain, our mills are supplied with maize from local

crops.

On arrival, the dump trucks are taken over by the weighbridge operators who ensure that the raw

materials are transported in good conditions then a quality analysis is carried out in our laboratories

to classify the quality of the maize.

SALES / BACK OFFICE

Fully available to meet the satisfaction of our customers, our sales and team and sales administration

work every day to offer the most suitable products for our customers' applications.

PRODUCTION

The employees of the Production Department are controlling our facilities that transform the maize

in finished products while respecting the specifications of our customers (quantity, quality,

deadlines).

SHIPPING

Once the products are available, the employees of the Shipping Department package the finished

products to ship to our customer’s bag, bulk, big bag, etc.

They are also in charge of loading the trucks/tanks/etc. While respecting the food safety guidelines.

MAINTENANCE

To maintain the production tools in perfect working order, our Maintenance Department works daily

on our installations to carry out preventive and curative maintenance actions.

SUPPORT TEAMS

All these operations are possible thanks to the support of the Security, Quality, Human Resources,

Communication and Finance Departments.

SUPPORT TEAMS

All these operations are possible thanks to the support of the Security, Quality, Human Resources,

Communication and Finance Departments.

OUR PROCESS

Being a maize mill means separating the different parts of the maize (germ, vitreous almond, floury almond, bran) to make the best use of them!

Here are the main steps:

First, the kernel is cleaned to remove its impurities.

The next phase consists in humidifying the germ to facilitate its separation.

After a rest period of several hours, the kernel can be processed.

Degerming: this operation is essential and allows to delicately separate the germs by fragmentation. The kernels are propelled against a perforated metal canvas, which makes them burst. This results in a mixture of germs, husks, almond fragments and flours.

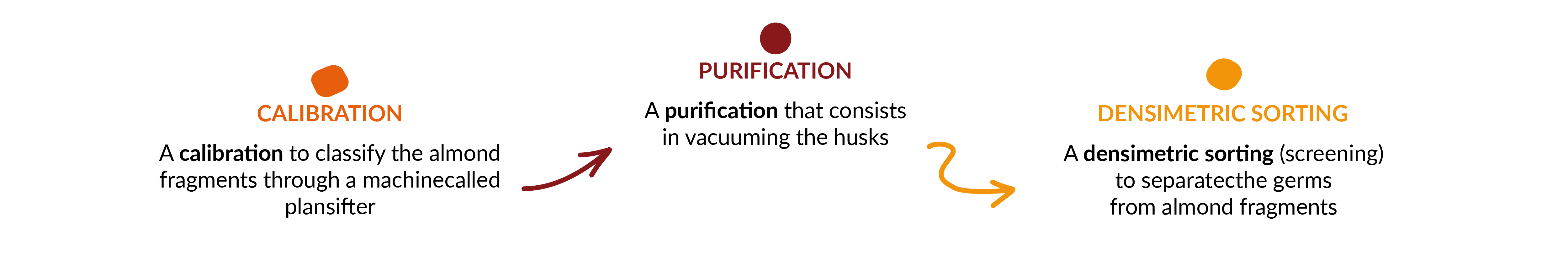

THEN, THE SEPARATION OF THE PRODUCTS IS MADE THROUGH THREE SUCCESSIVE OPERATIONS.

The degerminated almond fragments undergo successive crushing between cylinders.

The semolinas obtained are calibrated by sifting and screening, which makes it possible to separate the flours.

These operations are repetitive, in order to obtain products of regular and homogeneous grain size.

RESPONSABLE QUALITÉ

MAGASINIER

TECHNICIEN EN MÉCANIQUE

OUVRIER AGRICOLE

RESPONSABLE DÉVELOPPEMENT

RESPONSABLE RECHERCHE ET INNOVATION